Add to Cart

Description

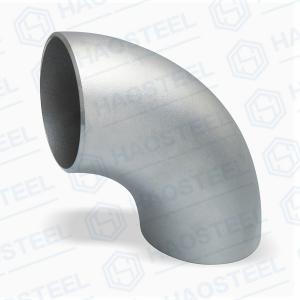

The difference between stainless steel elbow and carbon steel elbow is mainly the difference of material, its chemical composition will keep the surface of the elbow for a long time will not rust, will not be corroded. In piping systems, an elbow is a pipe fitting that changes the direction of the pipe. According to the Angle, there are 45° and 90°180° three commonly used, and according to the engineering needs, there are also 60° and other abnormal Angle elbows.

Elbow materials are cast iron, stainless steel, alloy steel, calcined cast iron, carbon steel, non-ferrous metals and plastics, etc. There are direct welding (commonly used) flange connection, hot melt connection, electric fusion connection, threaded connection and socket connection, etc. According to the production process, it can be divided into: welding elbow, stamping elbow, hot pressing elbow, push elbow, casting elbow, forging elbow, clamp elbow, etc. Other names: 90° bend, right Angle bend, love bend, white steel bend, etc.

The difference between stainless steel elbow and carbon steel elbow is mainly the difference of material, its chemical composition will keep the surface of the elbow for a long time will not rust, will not be corroded. According to the standard production can be converted into:

1. Production method: push, press, forging, casting, etc.

2, manufacturing standards: national standard, ship standard, electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

Forming process: forging; Stainless steel, nickel copper using cold processing, mandrel forming

Forming process: forging; cold pressing; mandril forming

Size range: Seamless, DN15 - DN600 (1/2" - 24"); Welded, DN15 - DN1200 (1/2" - 48")

Manufacturing Standard: National Standard: GB/T12459, GB/T13401, HG/T21635, HG/T21631

American Standard: ASME/ANSI B16.9MSS SP43

Japanese standard: JIS B 2311/2220

German standard: DIN2605/2616/2615/2617

Russian standard: GOST 17375/17376 and so on

Non-standard customized processing drawings are also acceptable

Material: stainless steel OCr18Ni9,0Cr18Ni9Ti,1Cr18Ni9Ti;304,304L,316,316L,316Ti,317,317L,321,321H,310,310S;1.4301,1.4306,1.4401,1.4435,1.4571,1.4436,1.4438,1.4541;08X18H10(0X18H10), 03X18H11(000X18H11),03X17H14M2 (000X17H13M2) ;08X18H10T(0X18H10T)

Duplex stainless steel ASTM A815-S31803, S32205, S32750, S32760

Super Stainless Steel ASTM 904L, B366-N08904, A403-WP317, 317L, 254SMO(UNS S31254)